Frequently Asked Questions

Great River Plastics Capabilities

Our Capabilities

- Sheet sizes up to 35″ x 39″

- Vacuum and Pressure Forming

- In-House Pattern and Mold Design

- Tooling and Prototyping

- Large Production Runs

- Material Gauge .007 to 0.060

- Forming of PVC, HIPS, PETG, PETE and HDPE

- Custom Colors, Products, and Assembly

- Fulfillment Services Available

What are the advantages of Custom Thermoformed Clamshell Packages?

- Custom thermoformed clamshell packages are designed to closely fit the shape of the retail product. Each package is created to the exact requirements of that particular product.

- The thermoformed packaging protects the product from damage through the entire process of shipping from the manufacturer through consumer purchase.

- The custom packaging allows for the manufacturer to include an insert card with product information and graphics which creates a more attractive presentation in retail stores.

- The correct type and thickness of plastic can be selected for the particular product being packaged.

- Recycled plastic materials may be used in the packaging.

- Different options for sealing the clamshell package are available and is best determined by the type and weight of the retail product and how the product will be displayed in retail stores.

How are clamshell packages sealed?

At Great River Plastics, we utilize several sealing options:

- Interference Fit (snap shut) full perimeter seal

- Interference Fit with button snaps

- Spot Weld

- Full Perimeter Weld

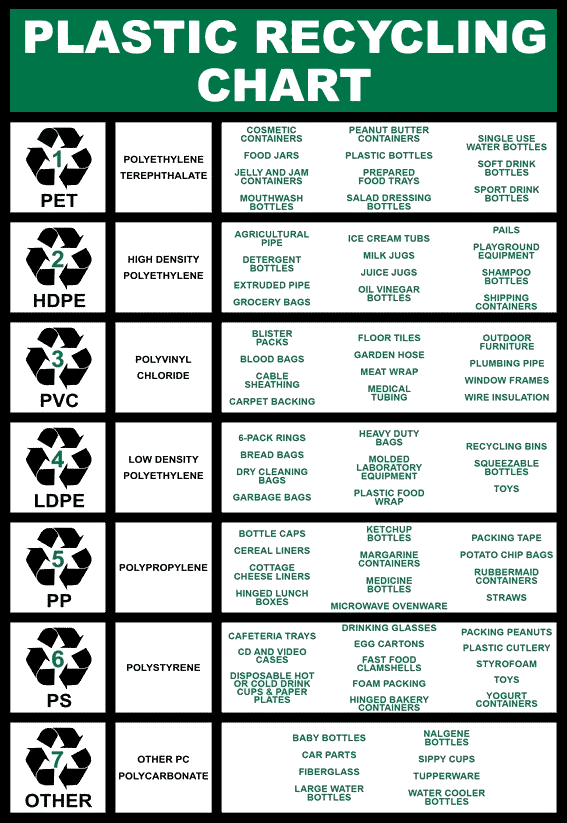

What plastics are recyclable?

A lot of information about recycling plastic materials can be found on numerous ecology and government websites. To simplify all that information, view our chart here or below that explains all the recycling identification numbers and what types of plastics are in each category.